Diving into the world of power supplies, the conversation about Switch Mode Power Supply (SMPS) versus traditional transformers is key for anyone deeply involved or just starting out. Getting to grips with what sets each apart, including their special features, uses, and the tech behind them, really matters when it comes down to how well your electronic devices work, how big they are, and how they perform. Both SMPS and transformers are all about turning electrical power into something we can actually use, but they go about it in very different ways. This means they each have their own pros and cons. This piece is here to highlight those differences, giving you the lowdown on why you might pick one over the other. As we get into the nitty-gritty of SMPS versus transformers, thinking about things like how efficient they are, how much space they take up, how much they cost, and what you specifically need them for, is crucial for choosing the right fit for your project.

What is SMPS (Switch Mode Power Supply)?

The Working Principle of SMPS

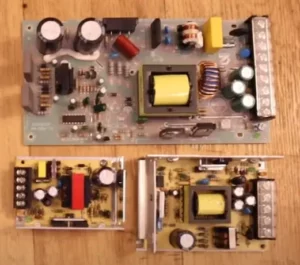

A Switch Mode Power Supply (SMPS) constitutes a pivotal component within the realm of power conversion technologies, offering an innovative methodology for the transformation of AC (Alternating Current) input voltage into DC (Direct Current) output voltage, and vice versa. Central to the operation of an SMPS is an array of electronic switches that are engaged in rapid oscillation, thereby regulating the quantum of energy transmitted to the output. Initially, the AC input is rectified to DC. Subsequently, through a process known as Pulse Width Modulation (PWM), this DC voltage is subjected to intermittent switching by transistors at elevated frequencies. The resultant high-frequency voltage is then meticulously regulated, rectified, and filtered to produce a stable DC output voltage.

The employment of high-frequency switching is particularly significant, as it obviates the need for voluminous magnetic components, thereby rendering the power supply unit more compact and lightweight. This feature delineates a marked departure from the conventional power supply mechanisms, which continuously modulate the input voltage, thereby incurring substantial energy dissipation in the form of heat. Such inefficiency necessitates larger heat sinks, further compromising the system’s efficacy and economy.

Advantages of Using SMPS

The perks of going with a switching power supply boil down to a few key advantages:

-

Enhanced Efficiency: Exhibiting proficiency with efficiency ratings surpassing 90%, Switch Mode Power Supplies (SMPS) significantly diminish energy dissipation. This attribute facilitates substantial savings on electrical expenditures while concurrently reducing thermal emissions.

-

Compact and Lightweight Design: Owing to its operation at elevated frequencies, SMPS necessitates diminutive magnetic components, resulting in a markedly reduced form factor and a lighter weight in comparison to conventional linear power supply units.

-

Adaptability: The versatility of SMPS is noteworthy. Capable of accommodating a diverse range of input voltages and adept at swiftly responding to fluctuations in power requirements, it proves to be an exemplary solution for a multitude of electronic apparatus and devices.

-

Reduced Thermal Output: As a consequence of its minimized conversion of energy into heat, SMPS obviates the need for extensive heat dissipation mechanisms. This characteristic contributes to its compact stature, enhancing its utility in space-constrained applications.

Common Applications of SMPS

SMPS technology is ubiquitously deployed across a plethora of domains, underscoring its remarkable versatility and efficacy. Predominant implementations encompass:

-

Consumer Electronics (e.g., TVs, computers, gaming consoles)

-

Portable Devices (e.g., laptops, smartphones)

-

Industrial Equipment

-

Medical Devices

-

Telecommunications Equipment

-

Power Tools

Each application benefits from the SMPS’s ability to provide stable and efficient power conversion in a compact form factor, making it an indispensable component in modern electronic design.

What is a Transformer?

How Transformers Work

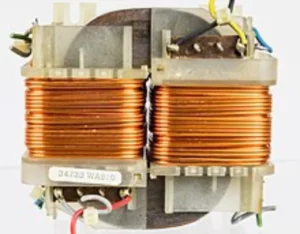

Think of a transformer as a device that moves electrical energy from one place to another without messing with the frequency. It’s like a magical box that has a couple of coils, or “windings,” snuggled around an iron heart. When you feed it AC voltage on the primary side, it creates a magnetic field in that iron heart. This magnetic charm then works its magic on the secondary side, creating a new voltage. If you need more or less voltage, you simply play around with the number of loops in those coils, making the transformer your go-to tool for either bumping up (stepping up) or dialing down (stepping down) the voltage. What’s cool is how efficiently this whole operation runs, thanks to the magnetic field being kept tight and tidy in the core. This makes transformers super useful, whether you’re dealing with gadgets that need just a little bit of power or big machines that need a lot.

Benefits of Traditional Transformers

Conventional transformers are celebrated for a multitude of benefits, paramount among these being:

-

Simplicity and Dependability: Characterized by their absence of mechanical components and a fundamental architecture, transformers are commendably reliable and exhibit remarkable longevity.

-

Elevated Efficiency: These devices proficiently conduct power transfer, manifesting minimal energy dissipations—thus, they are exceptionally suited for the provision of electricity over extensive distances.

-

Galvanic Isolation: Transformers confer galvanic isolation between the input and output, significantly augmenting safety measures by obviating a direct electrical linkage. This feature is indispensable for the prevention of electrical shock and the mitigation of power surges.

-

Adaptability in Power Capacities: Demonstrating an aptitude to manage an extensive spectrum of power capacities, transformers are versatile in their applications. This ranges from diminutive transformers integral to consumer electronic devices to colossal units pivotal in power distribution networks.

-

Enhanced Safety Measures: Due to their intrinsic safety characteristics, transformers are eminently appropriate for deployment in environments that demand stringent safety protocols, including healthcare facilities and industrial sites. This ensures not only the protection of sensitive equipment but also the well-being of personnel operating within such locales.

Transformer Applications

Transformers are integral to numerous applications, effectively managing power needs across different sectors:

-

Power Distribution

-

Electrical Isolation

-

Medical Equipment

-

Industrial Machinery

-

Audio Systems

Key Differences Between SMPS and Transformers

-

Efficiency: Generally, SMPS are more efficient than transformers. This boost in efficiency comes from how SMPS work—they switch power really fast with transistors, cutting down on wasted energy. On the flip side, transformers are still pretty efficient but tend to lose more power than heat, especially when they’re working really hard or barely at all.

-

Size and Weight: SMPS tend to be smaller and lighter, thanks to their efficient design that doesn’t need as much bulk to do its job. Transformers, on the other hand, have to have a core and coils, making them bigger and heavier.

-

Power Handling: When it comes to dealing with a lot of power without losing efficiency, transformers are the go-to. They can handle heavy lifting without breaking a sweat. SMPS are also up for the task, but they might need some tweaks to manage really high power levels, which could affect how big or expensive they are.

-

Electromagnetic Interference (EMI): SMPS can stir up more EMI because they switch on and off so quickly. But the good news is that newer SMPS designs are getting better at keeping that interference in check. Transformers are naturally quieter on the EMI front, making them a better fit for gadgets that need to keep things super quiet.

-

Cost: At first glance, SMPS might seem pricier because they’re complex to design and make. But their efficiency means they could save you money on energy costs in the long run. Transformers might be cheaper to get started with, but they could end up costing more over time because they’re not as efficient.

-

Flexibility: SMPS are pretty versatile—they can handle a variety of voltages, both in and out, and you can adjust them as needed. Transformers are a bit more set in their ways; if you want to change the output voltage, you’ll need to physically alter them.

-

Safety and Reliability: Transformers are known for being super reliable and safe because they’re straightforward and don’t have parts that move. SMPS can also be reliable and safe, as long as they’re designed well, but they have more complex parts that could potentially fail.

To summarize these differences in a structured format, the following table offers a direct comparison:

|

Feature

|

SMPS

|

Transformer

|

|

Efficiency

|

Higher

|

Lower

|

|

Size and Weight

|

Smaller and Lighter

|

Larger and Heavier

|

|

Power Handling

|

Suitable for low to medium power

|

Better for high power

|

|

EMI

|

Higher (with improvements)

|

Lower

|

|

Cost

|

Higher initial, lower operational

|

Lower initial, higher operational

|

|

Flexibility

|

High (adjustable output)

|

Low (fixed output)

|

|

Safety and Reliability

|

High (with proper design)

|

Very High

|

Design Considerations and Performance Metrics: SMPS vs. Transformer

Within the realm of electronic design, the decision to employ a SMPS over a conventional transformer is dictated by an array of critical considerations, ranging from the requisite output voltage to the dimensional limitations inherent to the project. The SMPS, distinguished by its utilization of switching regulators, presents a streamlined, diminutive solution adept at the proficient conversion of electrical power to the requisite direct current (DC) output voltage. This attribute renders it exceedingly advantageous for applications where spatial economization is crucial. In stark contrast, traditional transformers, dependent on linear regulators and an iron core, transmute alternating current (AC) into direct current (DC), frequently culminating in greater volumetric dimensions owing to the requisite physical materials. The deliberations progress to encompass the architecture of the power supply topology, wherein the SMPS frequently adopts a flyback converter for applications necessitating lower voltages, offering reduced acoustic emissions and augmented efficiency across an expansive spectrum of frequencies (kHz to MHz). This stands in marked contrast to the more rudimentary, albeit bulkier, design paradigm of power transformers which, despite their durability and lower susceptibility to magnetic saturation (hysteresis), frequently fall short in replicating the efficiency and compactness advantages proffered by their SMPS counterparts.

Team of experts in this domain exploit an assortment of analytical instruments and simulations to prognosticate the performance metrics of these power supply mechanisms, diligently considering variables such as voltage output, the incorporation of capacitors and inductors to mitigate fluctuations, and the resilience of components like copper coils and diodes. The selection between a switch mode transformer and a traditional power transformer typically converges on the specific requirements for a direct current supply dictated by the application, with the SMPS emerging as the superior choice in scenarios which mandate elevated efficiency, reduced dimensions, and diminished noise production. Conclusively, this selection process is steered by an exhaustive evaluation of each technology’s performance indicators, including their proficiency in delivering the stipulated output voltage whilst adhering to the constraints imposed by size, mass, and acoustical output, thereby ensuring that the ultimate design configuration satisfies the exigent specifications demanded by contemporary electronic apparatuses.

FAQs

What are the main differences between SMPS and transformers in terms of efficiency?

For efficiency, let’s take a hypothetical example: An SMPS can achieve high efficiency, typically ranging from 90% to 99%, under optimal conditions, whereas a traditional transformer’s efficiency might range between 85-90% for similar power levels. For instance, an SMPS designed for a laptop might use only about 5-10% of electrical energy as lost heat, whereas a high voltage transformer-based power supply could lose 10-15% due to saturation and power loss. This difference becomes more pronounced in applications where energy efficiency is critical, such as in battery-powered devices where every percent of efficiency gain translates to longer battery life.

Can SMPS replace traditional transformers in all applications?

Considering application specificity, SMPS units are favored in compact, portable electronics like smartphones, where they provide the necessary power in a small footprint without generating excessive heat. On the other hand, transformers are indispensable in high-power applications such as power distribution networks, where robustness and reliability over long periods are paramount. An example is the utility transformers used in electrical grids, designed to handle kilowatts to megawatts of power, far beyond what is practical for SMPS technology and traditional transformer topologies.

How do the costs of SMPS and transformers compare in the long run?

Cost-effectiveness can be illustrated by comparing operational costs. An SMPS, with its higher initial cost, may offer lower energy consumption and thus lower operating costs over a 5-year period. For example, in an industrial setting, using SMPS-based power supplies for control systems could result in energy savings that offset the higher initial price, compared to traditional transformers, which, while cheaper upfront, incur higher electricity costs due to low efficiency in power conversion.

Which is better for high-frequency applications, SMPS or transformers?

High-frequency applications such as RF communication devices prefer SMPS for its ability to efficiently handle varying loads and frequencies. A practical example is the use of SMPS in mobile phones, where the power supply must adapt quickly to the changing demands of the processor and radio modules without generating interference that could affect the phone’s communication capabilities.

How do SMPS and transformers fare in terms of electromagnetic interference (EMI) and radio frequency interference (RFI) control?

The management of EMI and RFI is of paramount importance for the functionality of sensitive electronic equipment. Owing to the rapid on-and-off switching mechanism inherent to SMPS, there is typically a requisite for additional filtering measures to attenuate EMI and RFI emissions. For instance, in the context of a medical device such as an MRI scanner, the integration of SMPS equipped with exemplary EMI filtration capabilities is crucial to prevent any compromise in the fidelity of the images it generates. Conversely, transformers, operating at relatively lower frequencies, inherently produce lesser EMI, thus emerging as the preferred option in applications where minimizing interference is imperative, such as in audio amplifiers. In such scenarios, any superfluous noise can significantly degrade the audio quality.

Conclusion