Still not finding what you’re looking for?

Contact our consultants for more available products.

The measurement of the capacitive proximity switch like this is usually one pole plate that forms the capacitor, and the other pole plate is the housing of the switch. This housing is usually grounded or connected to the housing of the device during the measurement process.

When an object moves towards the proximity switch, regardless of whether it is a conductor or not, due to its proximity, the dielectric constant of the capacitance should always change, so that the capacitance changes and the state of the circuit connected to the measuring head also changes, so that the switch can be controlled on or off. This proximity switch detects objects that are not limited to conductors, liquids or powders that can be insulated, etc.

1. The temperature stability is good

The capacitance value of the capacitive proximity switch is independent of electrode material, which is helpful to choose the material with a low-temperature coefficient and has little influence on stability because of its small heat. But the resistance sensor has the copper loss, easy to generate heat zero drift.

2. Simple structure

The Capacitive Proximity Switches are simple in structure, easy to manufacture and ensure high accuracy, can be made very small to achieve some special measurement, can work in high temperature, strong radiation, and strong magnetic field, etc. , withstand high pressure, high impact, overload and so on; can measure the ultra-high temperature and low-pressure difference, can also measure the work with magnetic.

3. Good dynamic response

Because the electrostatic gravitation between the electrode plates is very small, about 10 ^-5 N, the Action Energy of the capacitive proximity switch is very small, and because its movable part can be made very small and thin, that is, its mass is very light, so its natural frequency is very high, the dynamic response time is short, can work under several megahertz frequencies, is especially suitable for the dynamic measurement. And because of its small dielectric loss can be used higher frequency power supply, so the system operating frequency is high. It can be used to measure the parameters of high-speed change.

4.Can be measured non-contact and has high sensitivity

Non-contact measurement of rotary shaft vibration or ECCENTRICITY, small ball bearings, such as radial clearance. When the non-contact measurement is used, the capacitive Proximity Switch has an average effect, which can reduce the influence of workpiece Surface roughness on the measurement.

In addition to the advantages mentioned above, the capacitive Proximity switch is sensitive because the electrostatic gravitation between the plates with electrodes is very small, the input force and energy required are very small, so it can measure very low pressure, force and small acceleration, displacement, etc. , high resolution, sensing 0.01 M or less displacement. Because of its low loss of air and other media, the zero residual is very small when the differential structure is connected to the bridge type, so it allows the circuit to be enlarged at high magnification, which makes the instrument have high sensitivity.

1: Capacitive proximity switch can theoretically detect any object, when detecting objects with high dielectric constant, the detection distance should be significantly reduced, then even increasing the sensitivity will not be effective.

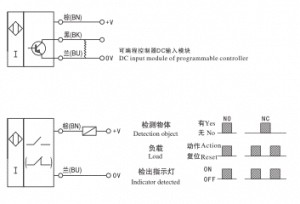

2: Capacitive proximity switch has an on time of 50ms, so in the design of user products, when the load and the proximity switch use different power supply, it is necessary to turn on the power of the proximity switch first.

3: When inductive loads (such as lamps, motors, etc.) are used, their transient inrush currents are large and may deteriorate or damage the AC two-wire capacitive proximity switch.

4: Do not use the proximity switch under a DC magnetic field of 200 Gauss or more to avoid malfunction.

5: DC two-wire proximity switch has a static leakage current of 0.5-1mA, and in some cases where the leakage current requirement of DC two-wire proximity switch is high, try to use DC three wire proximity switch.

6: Avoid using the proximity switch in chemical solvents, especially in the environment of strong acids and bases.

7: Our products are SMD process manufacturing, and after strict testing before leaving the factory, in general use will not be damaged. In order to ensure the occurrence of accidents, please check whether the wiring is correct and whether the approved voltage is rated before turning on the power.

8: In order to make the capacitive proximity switch work stably for a long time, because it is affected by moisture, dust and other factors, please make sure to carry out regular maintenance, including the detection of objects and proximity switch mounting position to see if there is any movement or loosening, wiring and connection parts are not in good contact, whether there is dust adhesion.