An exhaustive market analysis executed by Grand View Research accentuates the escalating importance of proximity sensors. This is evidenced by a global market valuation of USD 3.9 billion in 2020, with projections pointing towards a vigorous compound annual growth rate (CAGR) of 7.3 from 2021 to 2028. This marked expansion is predominantly attributable to the soaring demand for advanced automation solutions and safety enhancements across various sectors, coupled with the swift expansion of the Internet of Things (IoT) industry.

As we ventured into 2021 and subsequent years, these devices have gained exceptional prominence across a multitude of industries, encompassing but not restricted to automotive, manufacturing, and consumer electronics sectors.

Proximity Sensor: What is It?

Working Principles of Proximity Sensors

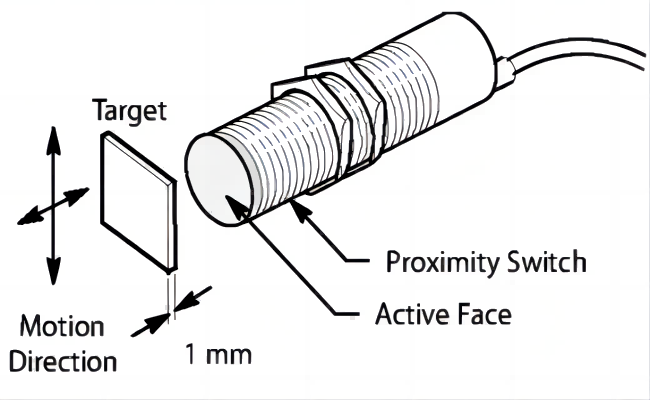

This ingenious technology enables target detection without necessitating any physical contact, rendering proximity sensors, specifically contactless sensors, exceptionally suitable for applications where robustness and non-contact sensing are paramount considerations.

Different Types of Proximity Sensors

Capacitive Proximity Sensors: These sensors exhibit the capability to discern both metallic and non-metallic objects by discerning alterations in the dielectric constant within their surroundings.

Inductive Proximity Sensors: Meticulously engineered for the exclusive purpose of identifying metallic entities through the utilization of electromagnetic fields engendered by an intricately wound coil.

Ultrasonic Proximity Sensors: Employ acoustic waves to discern the presence of objects and meticulously gauge their spatial separation.

Magnetic Proximity Sensors: Discern the presence of magnetic or magnetized entities, often enlisted for monitoring the positional status of mobile components.

Infrared Proximity Sensors: Prevalent in consumer electronics, these sensors harness the potency of infrared radiation to impeccably identify objects and are frequently deployed for close-range detection.

Laser Proximity Sensors: Harness laser light to impeccably identify objects, serving as an indispensable tool in applications mandating precise distance measurement.

|

Type

|

Vibration Tolerant

|

Sensitivity

|

Advantages

|

Limitations

|

|

Capacitive Proximity Sensors

|

Moderate

|

High

|

High sensitivity;

can detect through non-metallic materials

|

Sensitive to environmental changes like humidity

|

|

Inductive Proximity Sensors

|

High

|

Moderate to High

|

Robust in harsh environments;

immune to non-metallic materials

|

Only detects metallic objects

|

|

Ultrasonic Proximity Sensors

|

Moderate

|

Moderate

|

Unaffected by color or transparency of objects;

long-range sensing

|

Affected by environmental noise and surface angle

|

|

Magnetic Proximity Sensors

|

High

|

Moderate

|

Highly reliable for detecting magnetic objects

|

Limited to magnetic objects only

|

|

Infrared Proximity Sensors

|

Low

|

Moderate

|

Effective for close proximity detection;

low power consumption

|

Affected by ambient light and heat sources

|

|

Laser Proximity Sensors

|

Moderate

|

Very High

|

High accuracy and precision;

unaffected by most surface colors

|

Can be affected by reflective surfaces;

higher cost

|

Proximity Sensor Applications in Industrial Automation

Industrial automation systems extensively incorporate various types of proximity sensors, serving as pivotal elements for enhancing efficiency and precision. These sensors are integral in assembly lines, adeptly monitoring the presence and position of parts, a critical aspect for automated assembly processes. In packaging applications, they utilize their capacity to detect the presence of items, thereby controlling machinery for meticulous placement and packaging. Furthermore, within the realm of quality control, proximity sensors are indispensable, employed to verify the presence and alignment of components on a conveyor belt. This ensures adherence to stringent quality standards, including object detection, under diverse environmental conditions.

Proximity Sensor in Valve Equipment

Proximity Sensors in the Food and Beverage Industry

Proximity Sensors in the Textile Industry

Moreover, within the intricate realms of fabric tension control systems, these sensors play an indispensable role. They are crucial in consistently maintaining optimal tension levels throughout the weaving or knitting processes. This aspect is of paramount importance for ensuring the superior quality of fabrics, as any deviation in tension can significantly affect the structural integrity and aesthetic appeal of the textile.

Additionally, proximity sensors are vital in ensuring the uninterrupted and fluid progression of fabrics along production lines. This feature guarantees a continuous and efficient manufacturing process, enhancing both productivity and the overall quality of the end product.

Proximity Sensors in the Automotive Industry

Their deployment in this context stands as a testament to their exceptional capacity to discern and interpret the proximity of nearby objects with remarkable precision. This capability assumes paramount importance in aiding drivers during intricate parking maneuvers, thereby substantially diminishing the risk of inadvertent contact with obstacles. Moreover, these sensors are integral components of various safety mechanisms, including automatic braking systems. They adeptly measure the proximity of neighboring vehicles or obstructions, playing a pivotal role in the mitigation of potential collision risks.

Home Automation and Security Systems

Within the purview of security applications, proximity sensors exhibit remarkable precision in detecting human presence, thus serving as a critical catalyst for alarm systems in the event of unauthorized ingress. This capability significantly fortifies the robustness of home security infrastructures, furnishing an intricate layer of defense against potential breaches.

Moreover, these sensors prove instrumental in the efficacious operation of HVAC systems, facilitating precise and responsive adjustments to ambient temperature settings contingent upon detected occupancy patterns. This not only elevates the residents’ comfort levels but also assumes a pivotal role in fostering energy conservation initiatives. The incorporation of proximity sensors in such contexts serves as a paradigmatic illustration of their utility in engendering a secure, comfortable, and environmentally conscientious domestic milieu.

Proximity Sensors in Environmental Monitoring

Pertaining to air quality surveillance, the role of these sensors is indispensable. They are instrumental in pinpointing airborne pollutants, thus providing indispensable data that is integral to comprehensive evaluations of environmental health. This intelligence is crucial in augmenting initiatives aimed at safeguarding public safety.

Manufacturing and Equipment Maintenance

In the sphere of equipment maintenance, proximity sensors are irreplaceable in their function of rigorously ensuring that machinery operations remain within the stipulated norms. This critical role is pivotal in accelerating the identification of incipient wear and looming failures, a crucial factor in maintaining operational efficacy and upholding stringent safety standards. Their detailed and continuous monitoring of machine performance introduces an additional layer of refinement to maintenance protocols, significantly elevating the precision and effectiveness of these processes.

Optimal Selection of Proximity Sensors for Diverse Applications

A paramount consideration revolves around the compatibility of the target material with the sensor technology in use. For instance, inductive sensors prove to be the quintessential choice for detecting metallic objects, owing to their reliance on variations in coil inductance induced by the proximity of a metallic target. Conversely, photoelectric sensors employ light emission methods and light detection through a light beam to discern the presence of objects, rendering them suitable for a diverse array of materials, contingent upon the presence of an unobstructed optical path.

Environmental conditions exert substantial influence on sensor selection. In scenarios characterized by extreme temperatures or dampness, the judicious selection of sensors engineered to withstand such adversities becomes imperative. Ultrasonic sensors are renowned for their adeptness in operating under damp conditions, whereas inductive sensors exhibit resilience in the face of extreme temperature fluctuations.

Another pivotal consideration pertains to the electrical signal and circuit prerequisites. Distinct sensor types generate disparate electrical signals, encompassing alternating current (AC), reflected light, or electromagnetic detection fields. It is of paramount significance to ensure that the electrical output of the sensor aligns harmoniously with the electrical circuitry of the application, encompassing primary components and semiconductor outputs.

Furthermore, the desired detection range warrants meticulous deliberation. Certain sensors, such as those predicated on magnetic field principles, proffer exceptional maximum detection ranges, including excellent max detection range with fast update rates, rendering them amenable to applications necessitating extended-distance detection capabilities. Conversely, photoelectric sensors are renowned for their expeditious update rates and are particularly well-suited for applications wherein precision and swiftness are of paramount importance.

In summation, the process of electing the most suitable proximity sensor necessitates a discerning evaluation of sensor classifications, target material characteristics, environmental contingencies, and electrical prerequisites. By meticulously weighing these factors and selecting from a plethora of available models, one can ensure the optimal performance of proximity sensors across diverse industrial applications, in strict adherence to established standards such as the Japanese Industrial Standards (JIS), while simultaneously achieving cost-effective solutions tailored to their specific needs.